Who we are?

At Quality Photonic Optics, we’re setting new industry standards through our proprietary technology of photonic integration. We specialize in the design, prototyping, and manufacturing of optical encapsulation for photonics components, utilizing advanced optical materials and a groundbreaking encapsulation manufacturing process. This unique approach enables us to produce optical components with superior qualities, such as enhanced light emission and detection capabilities, at unprecedented speeds.

Technology

Discover our cutting-edge technology!

Our solution

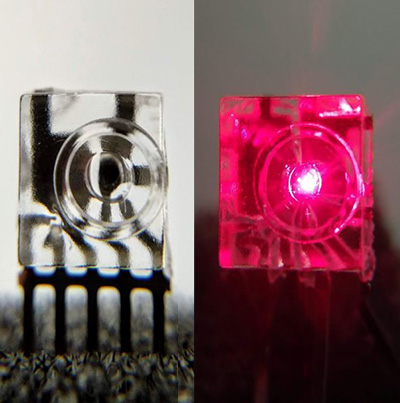

QPO introduces a groundbreaking approach to photonics manufacturing by employing a proprietary process that utilizes thermoplastics for encapsulating light emitters and detectors. This innovation not only ensures exceptional optical quality but also significantly enhances manufacturing efficiency—reducing the production time for each Fiber Optical Transceiver (FOT) component by 66% and achieving a 76% cost reduction for manufacturing LED lighting components.

Why Choose QPO?

Our unique encapsulation technology is safeguarded by four patents, providing a competitive edge unparalleled in the market. Our solutions are tailored to empower companies keen on integrating our cutting-edge technology, offering comprehensive services that include design, prototyping, manufacturing, and testing of client products.

Products & Services

Our offerings encompass a range of solutions tailored to your needs

Pilot Line Programs

Our pilot line programs are designed to seamlessly integrate our advanced optical encapsulation technology into your company’s operations. Tailored to meet your unique needs, these programs encompass design, prototyping, manufacturing, and testing, culminating in the establishment of a fully operational pilot line at your facility. This close partnership ensures a smooth adoption process, significantly enhancing product quality and production efficiency with our specialized support every step of the way.

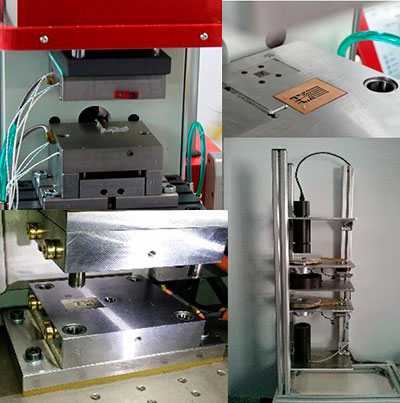

Machinery

QPO provides state-of-the-art machinery essential for revolutionizing optical manufacturing processes. Our equipment facilitates the encapsulation of optical components, improving production capabilities and product quality. Alongside our cutting-edge technology, we offer expert support for design, installation, and integration, ensuring our clients can maximize the benefits of our innovations with minimal disruption to existing operations.

Innovation and Research

Innovation is the cornerstone of QPO. We’re committed to pushing the boundaries of optical manufacturing through continuous research and development. Our collaborations with technological centers and universities fuel our journey towards pioneering new solutions and applications in the field.

Customizable photonic emitters integrated into a chip using new 3D encapsulation processes (FOTUNECHIP3D) “subsidized by the CDTI”

Development of a new industrial process for the encapsulation of electro-optical devices for distributed broadband information systems.

The encapsulations usually used require relatively high quantities of thermosetting materials, after the molding process and once the encapsulated component is removed from the cavity, they require a curing process, often in an oven for 4-5 h at an elevated temperature.

Under the financing of the RETOS-Collaboration program (RTC-2015-3954-8) of the Ministerio de Economía y Competitividad, they participate in the project “Desarrollo de un nuevo proceso industrial para el encapsulado de dispositivos electroópticos para sistemas distribuidos de información de amplio ancho de banda (ENCAP)” the National Microelectronics Center (CSIC), the Hybtronics Microsystems company and the CD6 of the Universitat Politècnica de Catalunya, with the main objective of replacing the curing process with a thermoplastic injection molding process.

The main competitive advantage that is expected from this new system are improvements in the field of manufacturing, reducing process times, and in the field of improving final performance, increasing the efficiency of the devices.

Micro-injection machine for Photonic Integrated Circuits encapsulation with optical performance using thermoplastic materials

Integrated circuits (IC), LED’s and Fiber optics devices make the world evolves faster and farther. One of the most important features of IC manufacturing processes is encapsulation. Its main goal is to protect, favour connectivity and dissipate heat, and help in the installation procedures, its importance is one of the highest within the value chain of electronics. Within the whole world of applications of IC, those related to Photonics (PIC) are in an exponential growth thanks to its speed and costs.

Currently, encapsulation of PIC is made through mould injection of thermosetting plastics. Nevertheless, injection processes require a very high processing time, due mainly to the curation process of the thermosetting plastic. Thus, manufacturing time, costs and precision, become the main problems of that technology for growing in an efficient and sustainable way.

Within this project entitled Micro-injection machine for Photonic Integrated Circuits encapsulation with optical performance using thermoplastic materials (PRODUCTE), and under the funding of the program Convocatòria d’Industria del Coneixement for the year 2016, Modalitat B, Producte, of the Agencia de Gestió d’Ajuts Universitaris i de Recerca, we have developed a brand new methodology for the manufacturing of photonic integrated circuits with embedded optical elements.

Address

C/ Sant Quirze, 91

08221 Terrassa, Barcelona

Phone Number

+34 902 36 58 92

info@qpolens.com